What I Wish I’d Known About Tattoo Paper Before Wasting $500 on Bad Stencils

Most people obsess over tattoo machines and inks, but I learned the hard way that the paper behind every great tattoo is where the real magic happens. After years of struggling with stencils that wouldn’t stick, transfers that looked like someone sneezed on them, and way too much money wasted on materials, I’m sharing what I’ve figured out about this overlooked world that separates amateur disasters from professional-quality transfers that actually work.

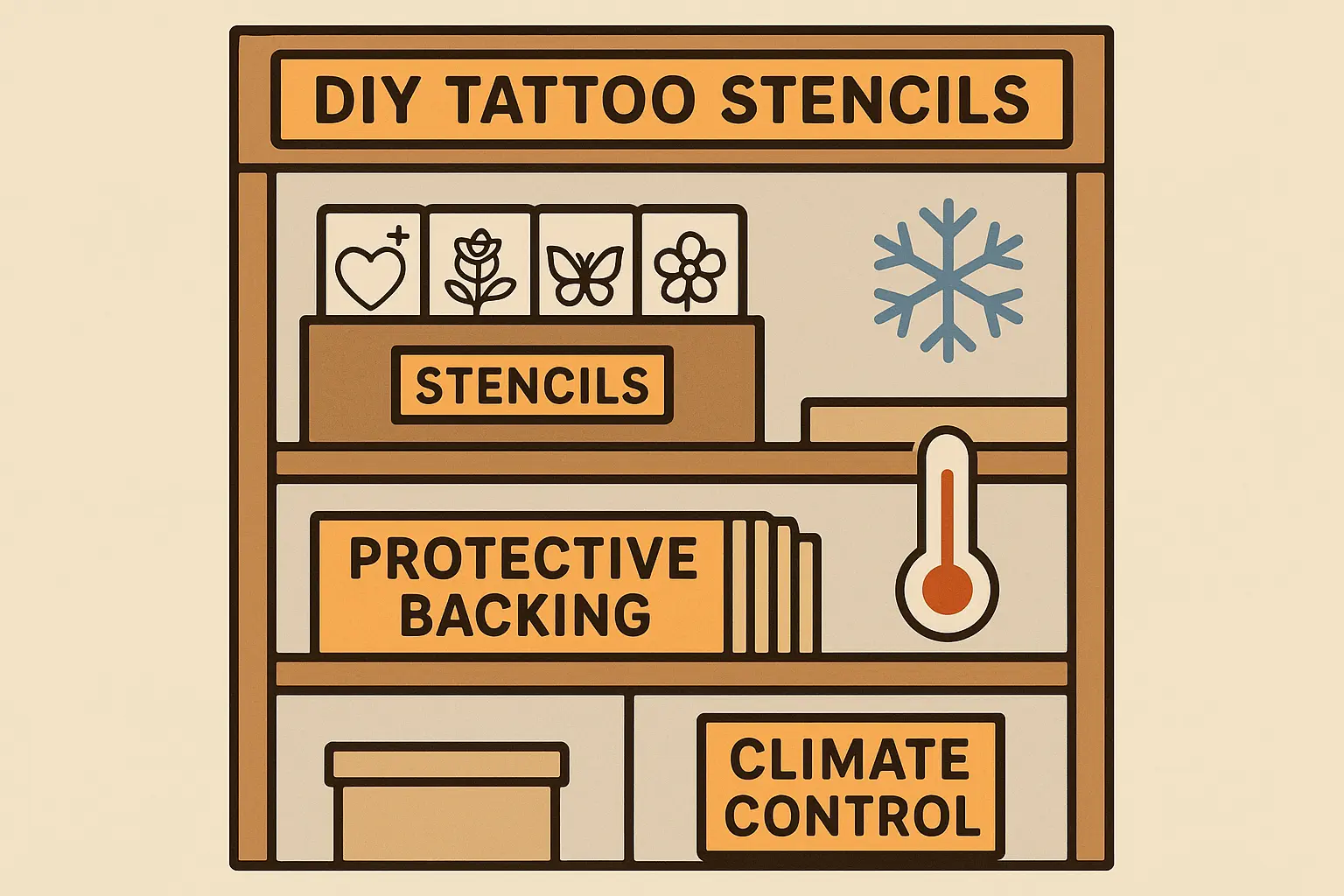

Modern tattoo papers can maintain quality for up to 1-2 years when stored properly in cool, dry conditions, making proper storage protocols essential for professional results. According to Sunnyscopa, unused tattoos will last up to 1-2 years if kept in the right conditions, highlighting the importance of proper storage protocols for professional tattoo operations.

Table of Contents

-

The Surprising Science Behind Your Thermal Printer

-

Why Temporary Tattoo Paper Isn’t Just for Kids Anymore

-

Precision Cutting Systems That Put Thermal Printing to Shame

-

DIY Tattoo Paper Hacks That Actually Work

-

Professional Workflow Secrets Most Shops Get Wrong

TL;DR

-

Your thermal printer needs precise temperature control (180-220°F) – just 10 degrees off ruins everything

-

Modern temporary tattoo papers are professional testing tools that can save you hundreds in revision costs

-

Computer-controlled cutting achieves 0.1mm precision, which is insane compared to thermal printing

-

DIY methods can work, but you need to understand the science (I learned this the expensive way)

-

Professional shops need systematic quality control and proper storage – humidity above 60% kills your paper

-

Multi-layer stencil systems will change how you approach complex tattoos

-

Environmental factors matter way more than anyone tells you

The Surprising Science Behind Your Thermal Printer

I can’t tell you how many times I’ve cursed at my thermal printer when a stencil came out looking like someone dragged a wet finger across it. For the longest time, I thought it was the printer being moody or the paper being cheap. Turns out, there’s actually a lot more going on inside that little machine than I thought, and understanding it completely changed my results.

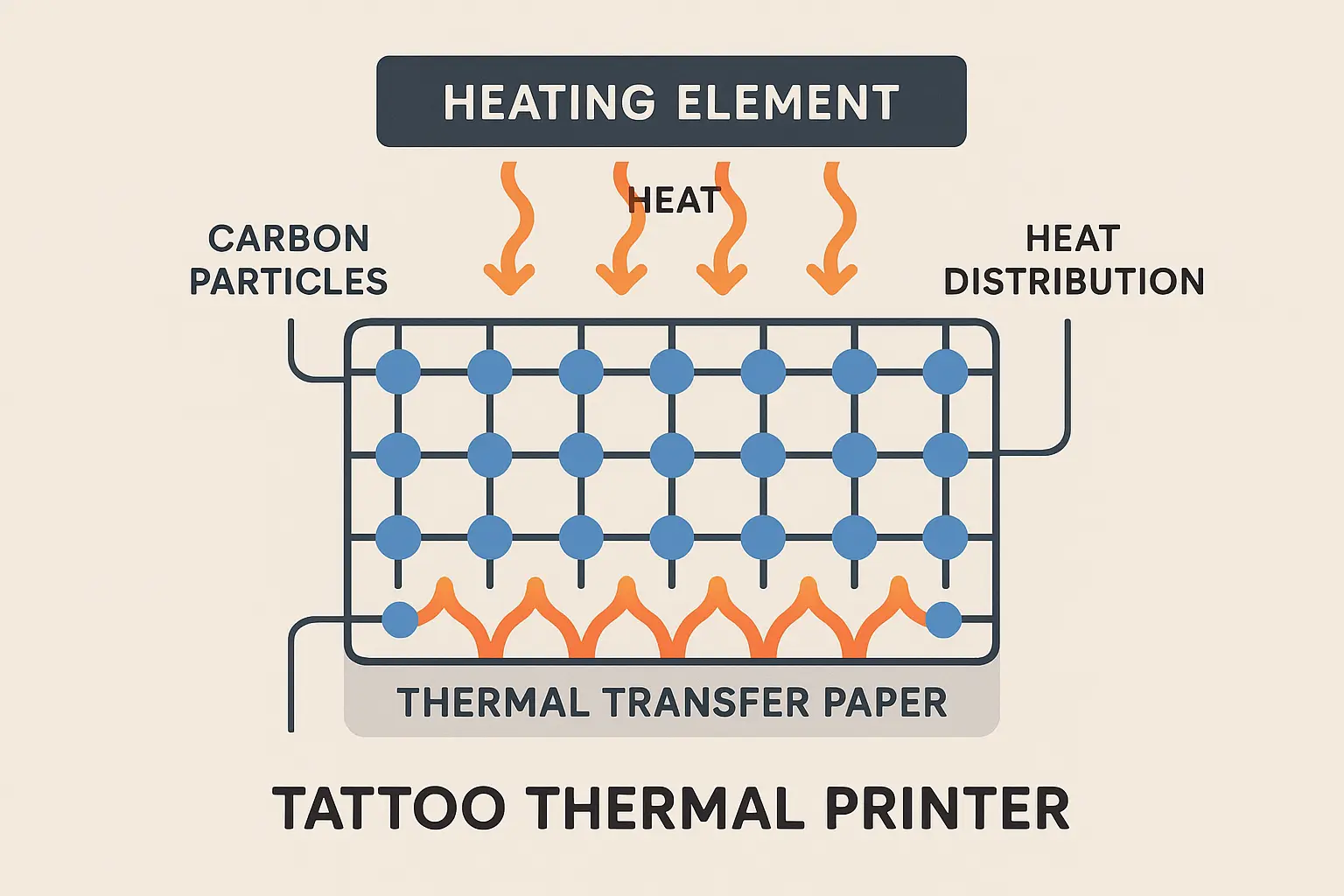

I used to just press print and hope for the best. Now I know that the interaction between heat, carbon particles, and timing determines whether your stencil will be crisp perfection or a blurry mess that’ll make you want to throw the whole thing in the trash.

How Carbon Particles and Heat Create Perfect Lines

Here’s something that blew my mind: the tiny particles in the ink need to be just the right size – think of it like flour for baking. Too fine and it won’t stick properly, too coarse and it clumps up and makes a mess. The sweet spot is between 15-40 nanometers, which is incredibly small.

I went through probably 20 different paper brands in my first year, and let me tell you – some of them were absolute garbage. I’d get a stencil that looked perfect, then halfway through a session it would start looking like someone dragged a wet finger across it. Took me way too long to realize it wasn’t me being clumsy – it was cheap paper with inconsistent carbon distribution.

|

Carbon Particle Size |

Transfer Quality |

What Actually Happens |

|---|---|---|

|

< 15 nanometers |

Terrible |

Gaps in lines, incomplete transfer |

|

15-40 nanometers |

Perfect |

Clean, consistent lines |

|

> 40 nanometers |

Awful |

Bleeding, smudgy mess |

Why Particle Size Makes or Breaks Your Stencil

When those carbon particles are outside that magic 15-40 nanometer range, you’re going to have a bad time. Bigger particles cause bleeding and make your lines look like they were drawn with a dying marker. Smaller ones don’t transfer completely, leaving you with gaps that’ll drive you crazy during application.

The Temperature Sweet Spot You’re Probably Missing

Most professional thermal tattoo paper works best between 180-220°F, but here’s what shocked me: just 10 degrees of variation can completely screw up your transfer quality and how long your stencil stays put on skin.

My friend Jake runs a shop in Portland, and he was going crazy trying to figure out why some days his stencils were perfect and other days they looked like trash. Same paper, same designs, but totally different results. Turns out his printer was running hot – just 15 degrees too hot – and it was screwing up about a third of his transfers. Cost him hundreds in wasted materials before he figured it out.

The Chemistry That Happens Faster Than You Can Blink

Multiple coating layers interact through lightning-fast chemical reactions during printing. This process happens faster than you can blink, yet it determines whether your stencil will last through an entire tattoo session or start peeling halfway through. It’s not just “heat makes ink stick” – there’s actual chemistry happening in there.

Material Engineering That Makes Stencils Actually Stick

Here’s something that drove me nuts when I was starting out: the stencil either wouldn’t stick at all (and would slide around while I’m trying to work), or it would stick so well that removing it felt like I was waxing my client. The engineering behind tattoo paper involves balancing multiple things that seem to fight each other.

The adhesive has to be strong enough to stay put through sweat, cleaning solutions, and hours of work, but gentle enough that you’re not torturing your client when it comes off. Getting this balance right is harder than you’d think.

The Adhesive Balancing Act Nobody Talks About

There’s this sweet spot where the adhesive is strong enough to stay put through a whole session but won’t leave someone looking like they got attacked by a band-aid. Medical-grade adhesives have to be tacky enough for secure attachment but gentle enough for removal without skin irritation. Took me forever to find papers that got this right.

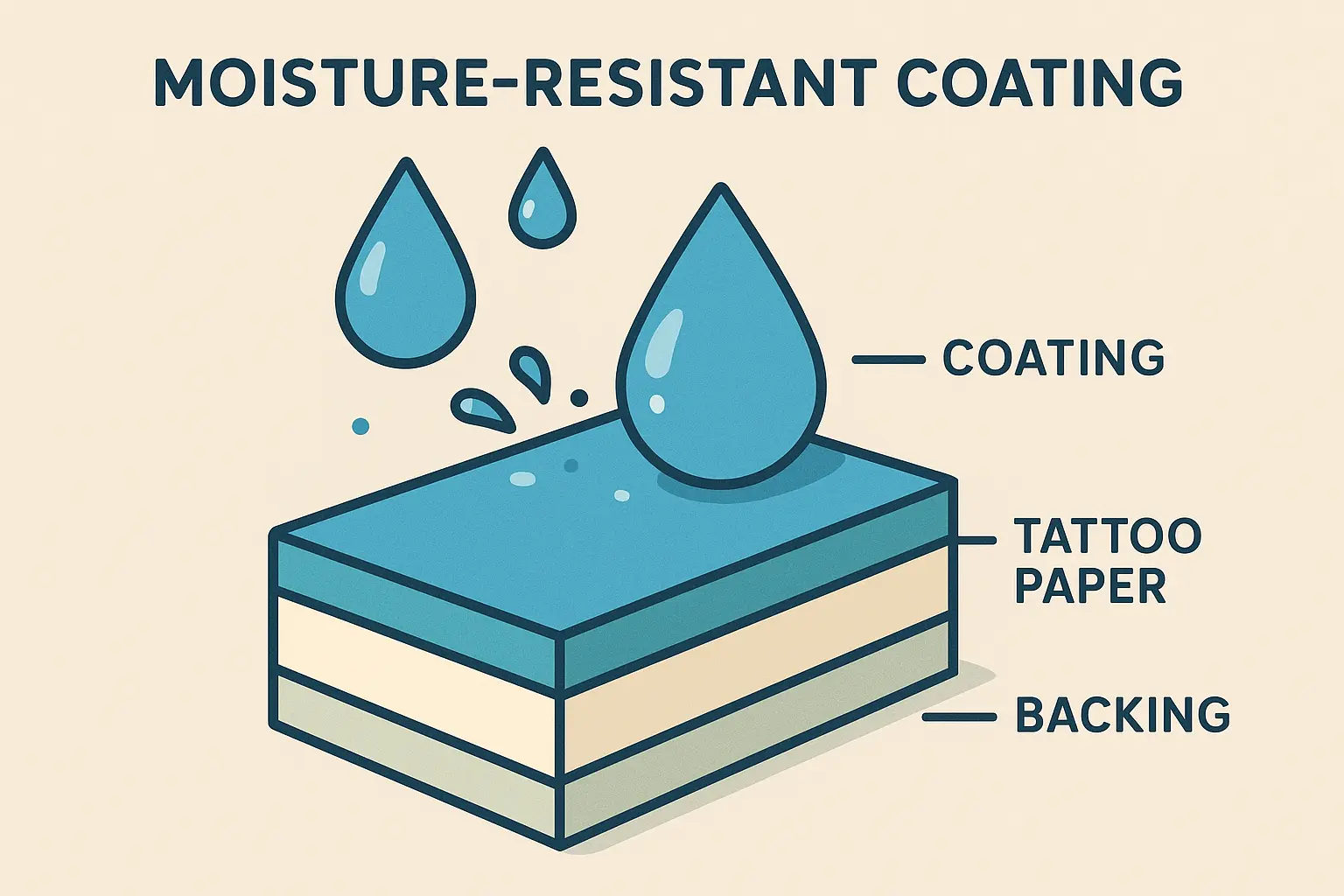

Moisture-Proofing Without Suffocating Skin

Advanced polymer coatings protect stencils from perspiration and cleaning solutions while still letting the skin breathe. This prevents that gross bacterial buildup underneath that nobody wants to deal with.

Why Your Digital Design Doesn’t Always Match the Stencil

I’ve seen countless artists frustrated when their beautiful digital artwork becomes a muddy mess on tattoo paper. The problem usually isn’t the design itself – it’s not understanding the physical limitations of the transfer process.

Converting digital tattoo designs to physical stencils involves considerations of scale, resolution, and line weight that directly affect final tattoo quality. I learned this through a lot of trial and error, and it would’ve saved me tons of time if someone had explained it upfront.

Working Around the 300 DPI Limitation

Most thermal printers max out at 300 DPI, which means you need specific design optimization techniques to maintain fine detail reproduction in complex artwork. Making things bigger isn’t always the solution – sometimes you need to simplify details that just won’t transfer properly.

Professional printers recommend using 600 DPI minimum for optimal tattoo stencil quality, which significantly exceeds the standard 300 DPI limitation of most thermal printers.

Why Temporary Tattoo Paper Isn’t Just for Kids Anymore

I used to think temporary tattoos were just kid stuff until an older artist showed me how he uses them for client consultations. Now I have clients wear a temporary version for a few days before we do the real thing. Saves me from having to fix placement issues later, and clients love being able to “test drive” their tattoo first.

The temporary tattoo paper market has exploded beyond novelty items into sophisticated professional testing systems. I’ve seen artists use advanced temporary papers to test placement and sizing before permanent work, and honestly, the material science behind these products is genuinely impressive.

Professional artists increasingly use temporary options for client consultations, similar to how simple tattoo designs help beginners visualize their first ink before committing to permanent artwork.

Recent breakthroughs in tattoo technology include “light-emitting tattoos” developed by researchers at University College London, which use organic light-emitting diodes (OLEDs) applied through water-transfer tattoo paper methods and could revolutionize both medical monitoring and fashion applications.

Medical-Grade Testing That Prevents Expensive Mistakes

Professional tattoo artists increasingly rely on advanced temporary tattoo paper to test placement, sizing, and client reactions before permanent application. These specialized formulations meet strict safety standards while providing realistic previews that save time and prevent costly revisions.

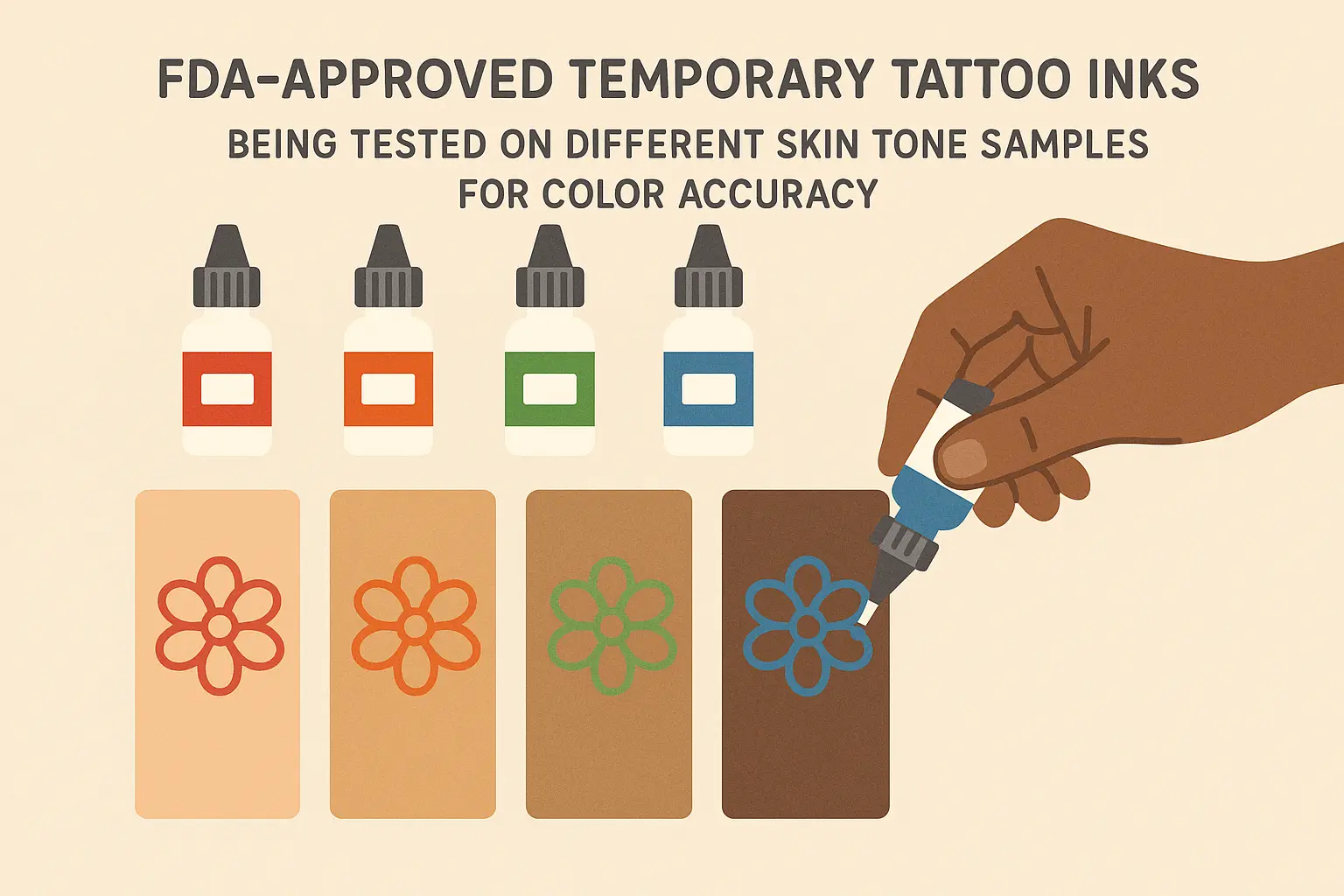

The chemistry behind medical-grade temporary tattoo paper involves biocompatible inks that won’t cause allergic reactions while still providing accurate color representation across different skin tones.

FDA-Approved Inks That Actually Look Real

Temporary tattoo paper inks have to meet FDA cosmetic standards while providing realistic color representation that accurately previews permanent tattoo appearance across different skin tones. This challenge requires way more sophisticated chemistry than you’d think.

Controlling How Long Temporary Tattoos Last

Modern temporary tattoo paper offers precise control over wear duration through engineered adhesive systems and ink penetration depths. You can now predict exactly how long a temporary tattoo will last and how it’ll fade, which is incredibly useful for client testing.

Advanced temporary tattoo systems can last 2-3 days with proper application, providing sufficient time for client testing and approval processes before permanent tattoo application.

Engineering Predictable Fade Patterns

Advanced temporary tattoo paper uses photodegradable components and skin pH interactions to create predictable fading patterns that actually simulate how real tattoos age over time. It’s pretty cool science.

Removal Chemistry That Won’t Damage Skin

Specialized removal solutions work through surfactant action and gentle solvents that break down temporary ink bonds without damaging your skin’s protective barrier. This approach proves much safer than scrubbing with harsh chemicals like some people try to do.

Precision Cutting Systems That Put Thermal Printing to Shame

I’ve watched cutting plotters create stencils with detail levels that would be completely impossible using thermal methods. The precision available through modern cutting technology transforms what’s possible in tattoo paper applications, and honestly, it’s kind of mind-blowing.

Computer-controlled cutting technology has revolutionized tattoo stencil creation, achieving accuracy levels that surpass traditional thermal printing methods. These systems enable intricate detail work and multi-layer stencil approaches that were previously impossible.

Computer Precision That Reaches 0.1mm Accuracy

Modern cutting plotters achieve incredible accuracy levels of 0.1mm, which is insane when you think about it. This enables tattoo paper stencils with detail levels that completely surpass what thermal printing can accomplish. We’re talking about precision that opens up possibilities for incredibly intricate designs that would be impossible with traditional methods.

The engineering behind these cutting systems involves servo motors, optical sensors, and software algorithms working together to maintain accuracy across thousands of cuts without any degradation in quality.

Blade Technology That Stays Sharp Through Thousands of Cuts

Tungsten carbide and diamond-coated cutting blades maintain precision through thousands of cuts while minimizing tattoo paper tearing and edge fraying that would ruin stencil quality. The engineering behind these blades is remarkable – they’re built to last.

Software That Optimizes Every Cut Path

Advanced algorithms optimize cutting paths to minimize paper movement and blade direction changes, reducing registration errors in complex multi-element designs that would otherwise be nearly impossible to align properly.

A professional tattoo artist in Los Angeles uses cutting software that automatically optimizes blade paths for a full-sleeve design, reducing cutting time from 45 minutes to 12 minutes while eliminating registration errors that previously required manual realignment.

Multi-Layer Stencil Systems That Organize Complex Work

Professional tattoo workflows increasingly utilize layered stencil systems that separate line work, shading guides, and color placement for complex pieces. This approach transforms how artists approach large, detailed tattoos by breaking them into manageable, organized layers.

Complex multi-session work benefits from systematic approaches, much like how arm tattoo planning requires careful consideration of design flow and session scheduling for optimal results.

Registration Marks That Ensure Perfect Alignment

Precision alignment systems use micro-perforated registration marks and optical alignment tools to ensure perfect layer registration across multiple stencil sheets. This precision becomes essential for complex multi-session work where everything has to line up perfectly.

Color-Coded Systems That Track Your Progress

Different paper colors and cutting depths create visual workflow systems that help artists track progress through complex multi-session tattoo processes, preventing confusion and missed elements. It’s like having a roadmap for complicated pieces.

|

Stencil Layer |

Color Code |

Purpose |

Typical Duration |

|---|---|---|---|

|

Outline |

Black |

Primary line work |

Session 1 |

|

Shading Guide |

Blue |

Shadow placement |

Session 2 |

|

Color Map |

Red |

Color boundaries |

Session 3-4 |

|

Detail Work |

Green |

Fine details |

Final session |

Specialized Papers Designed for Clean Cuts

Cutting applications require completely different tattoo paper properties than thermal printing, leading to specialized formulations optimized for clean cuts and precise detail retention. The paper science behind cutting-optimized materials is fascinating.

Paper manufacturers have developed specific formulations that resist tearing during cutting while maintaining the adhesive and transfer properties needed for professional tattoo applications.

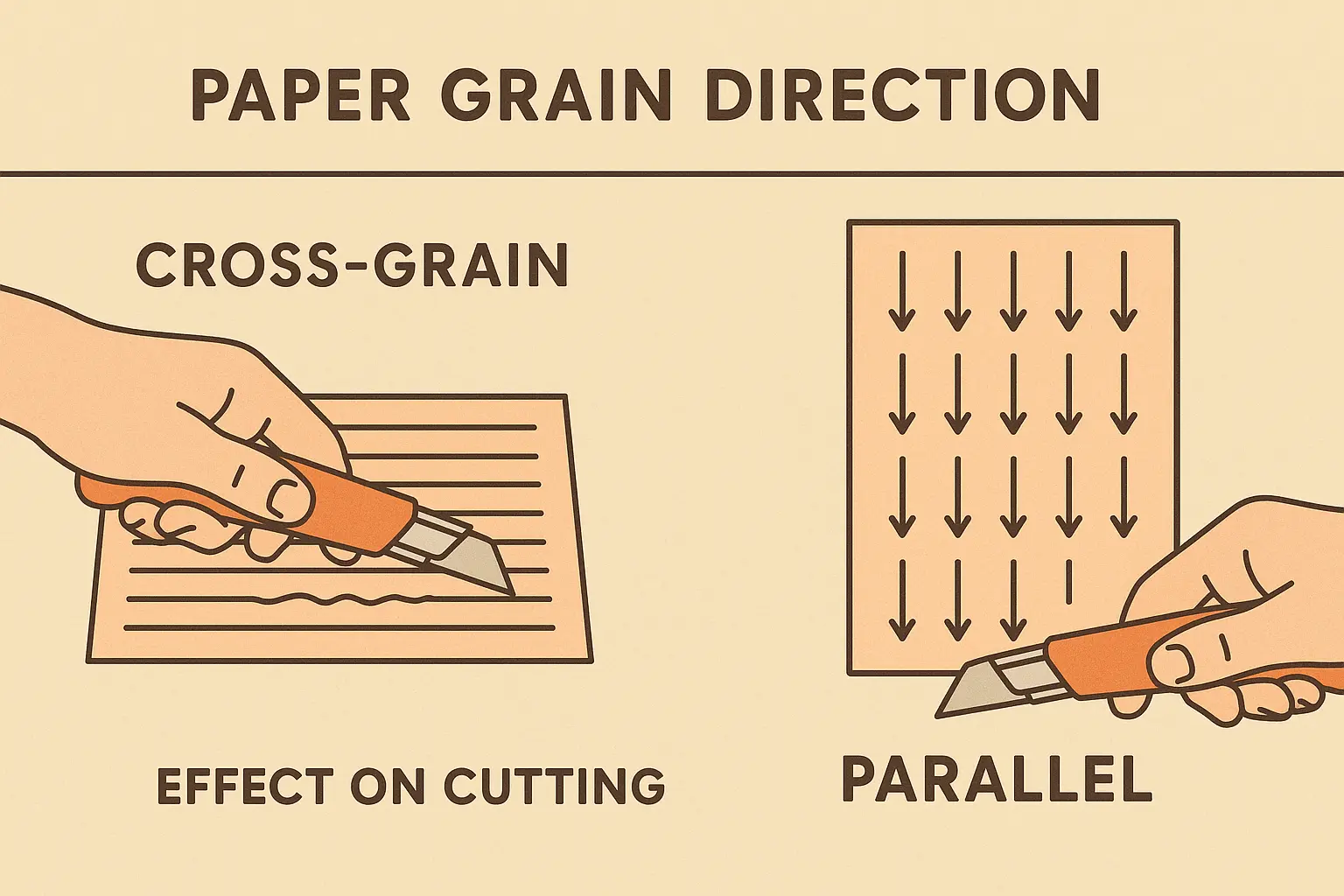

How Paper Grain Direction Affects Cut Quality

Paper grain direction significantly affects cutting quality. Cross-grain cuts produce cleaner edges but require 40% more cutting force than parallel cuts, which affects both blade wear and cutting speed. It’s one of those details that makes a big difference once you know about it.

DIY Tattoo Paper Hacks That Actually Work

I went down this rabbit hole of trying to make my own stencils at home, and wow, did I waste a lot of time and money. YouTube made it look so easy – just grab some carbon paper and a hair straightener, right? Wrong. My first attempts looked like a toddler’s art project. But I’m stubborn, so I kept at it until I figured out what actually works and what’s just internet BS.

The maker movement has spawned numerous techniques for creating tattoo stencils using household materials and accessible technology. While professional results require understanding underlying principles, I’ve discovered several DIY methods that can produce surprisingly good results when done correctly.

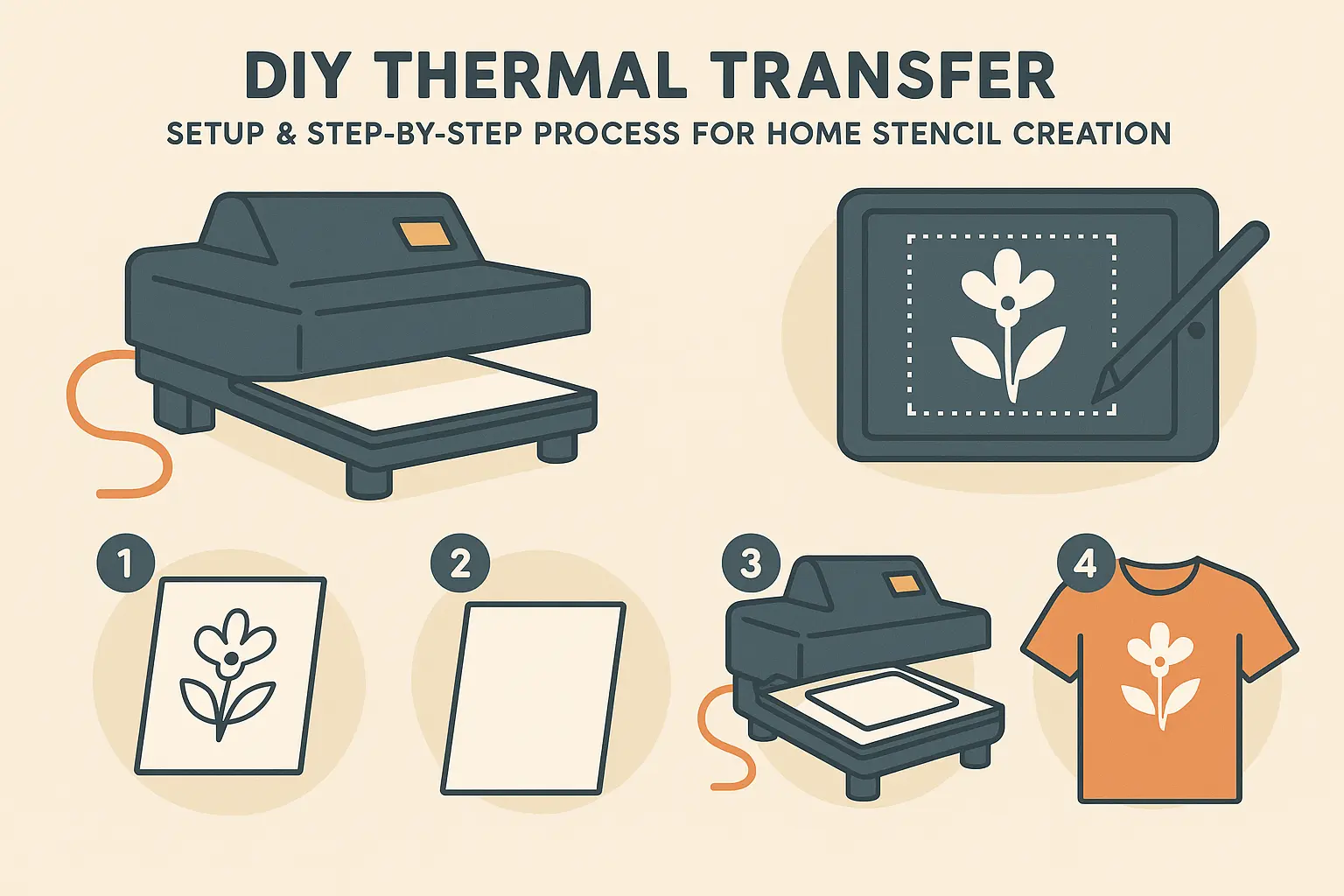

Modern tattoo artists like “Aaron Culpepper” from KSLA demonstrate how digital tools and traditional methods can work together, using Wacom tablets for digital design while still appreciating hand-drawn sketches on paper for certain creative processes.

I’ve spent months experimenting with various DIY approaches to understand what actually works versus what just wastes time and materials. The key lies in understanding the science behind professional methods and adapting those principles to accessible equipment.

Home Thermal Transfer Techniques That Don’t Suck

Consumer-grade thermal printers and modified materials can produce functional tattoo stencils, but you need specific modifications and techniques for professional-quality results. I’ve tested various approaches and found what actually works versus what just burns through your money.

The challenge with DIY thermal methods involves achieving consistent temperature control and proper carbon transfer without the precision engineering of professional equipment.

Printer Modifications That Make the Difference

Standard thermal receipt printers require firmware modifications and temperature adjustments to work effectively with tattoo-specific thermal papers and achieve proper transfer density. This process involves more complexity than just changing paper – you’re basically hacking your printer.

Alternative Heat Sources When You Don’t Have a Thermal Printer

Heat guns, modified hair straighteners, and specialized heating plates can substitute for thermal printers when properly calibrated for temperature and contact time. I’ve experimented with all of these methods, and some work better than others.

DIY Heat Source Checklist:

-

Temperature control between 180-220°F

-

Even heat distribution across surface

-

Consistent contact pressure

-

Timer for precise application duration

-

Safety equipment (heat-resistant gloves)

-

Test materials for calibration

Multi-Layer Chemistry That Happens in Milliseconds

Multiple coating layers interact through lightning-fast chemical reactions during printing, determining how cleanly carbon transfers while keeping the tattoo paper intact. There’s actual science behind getting this right, even with DIY methods.

Carbon Paper Methods That Still Work in 2024

Traditional carbon paper techniques remain viable for simple designs, with modern improvements in carbon formulations and application methods significantly improving results. Sometimes the old ways prove most reliable, especially when you’re just starting out.

The chemistry behind modern carbon papers has evolved considerably from the messy, inconsistent products of decades past. Today’s formulations offer controlled particle distribution and improved binding agents.

Getting Carbon Density Right Every Time

Optimal carbon transfer requires specific pressure applications (typically 15-20 PSI) and carbon particle sizes that prevent smudging while ensuring complete transfer. There’s actual science behind getting this right – it’s not just about pressing harder.

Digital-Physical Hybrid Approaches for Home Users

Combining digital design tools with physical transfer methods creates workflows accessible to home users while maintaining professional quality standards. These hybrid approaches offer the best of both worlds when executed properly.

Making Inkjet Printers Work for Tattoo Stencils

Modified inkjet papers with specialized coatings can accept tattoo-appropriate inks, though print head clogging and color accuracy remain significant challenges that require specific workarounds.

A home tattoo enthusiast in Denver created a hybrid system using an inkjet printer with modified photo paper and a heat press, achieving 85% of professional thermal printer quality at one-third the cost by understanding proper ink density and heat application timing.

Step-by-Step DIY Tattoo Paper Creation Process

Creating professional-quality tattoo stencils at home requires following specific steps that account for the chemistry and physics I’ve discussed. I’ve refined this process through trial and error, and these steps will save you from the frustration of failed transfers and wasted materials.

Understanding how to make a tattoo with paper involves more than just copying designs – you need to account for material properties, environmental conditions, and application techniques that determine success or failure.

Design Preparation That Sets You Up for Success

Converting digital artwork to high-contrast black and white while optimizing line weights for your chosen transfer method is crucial. This step determines whether your final stencil will have clean, consistent lines or frustrating gaps and bleeds.

Design Optimization Checklist:

-

Convert to high-contrast black and white

-

Optimize line weights for transfer method

-

Check resolution meets minimum requirements

-

Remove fine details that won’t transfer well

-

Test print on regular paper first

-

Adjust sizing for skin stretch considerations

Material Selection Based on Your Equipment

Choosing appropriate base paper (typically 20-24 lb weight) and carbon transfer medium based on your application method makes the difference between professional results and amateur-looking transfers that won’t stick properly.

Equipment Setup and Calibration

Calibrating thermal settings or pressure application tools to ensure consistent transfer without paper damage requires understanding the specific requirements of your materials and equipment combination.

Test Transfer Protocol

Creating small test pieces to verify transfer quality, adjusting temperature, pressure, or timing as needed prevents wasting expensive materials and ensures consistent results before working on client pieces.

Quality Control Inspection

Inspecting transfers for line consistency, edge definition, and adhesion properties before use catches problems early and maintains professional standards even with DIY methods.

Storage and Preservation Methods

Applying protective backing or storage methods to maintain transfer quality until application ensures your hard work doesn’t degrade before you can use the stencils.

Professional Workflow Secrets Most Shops Get Wrong

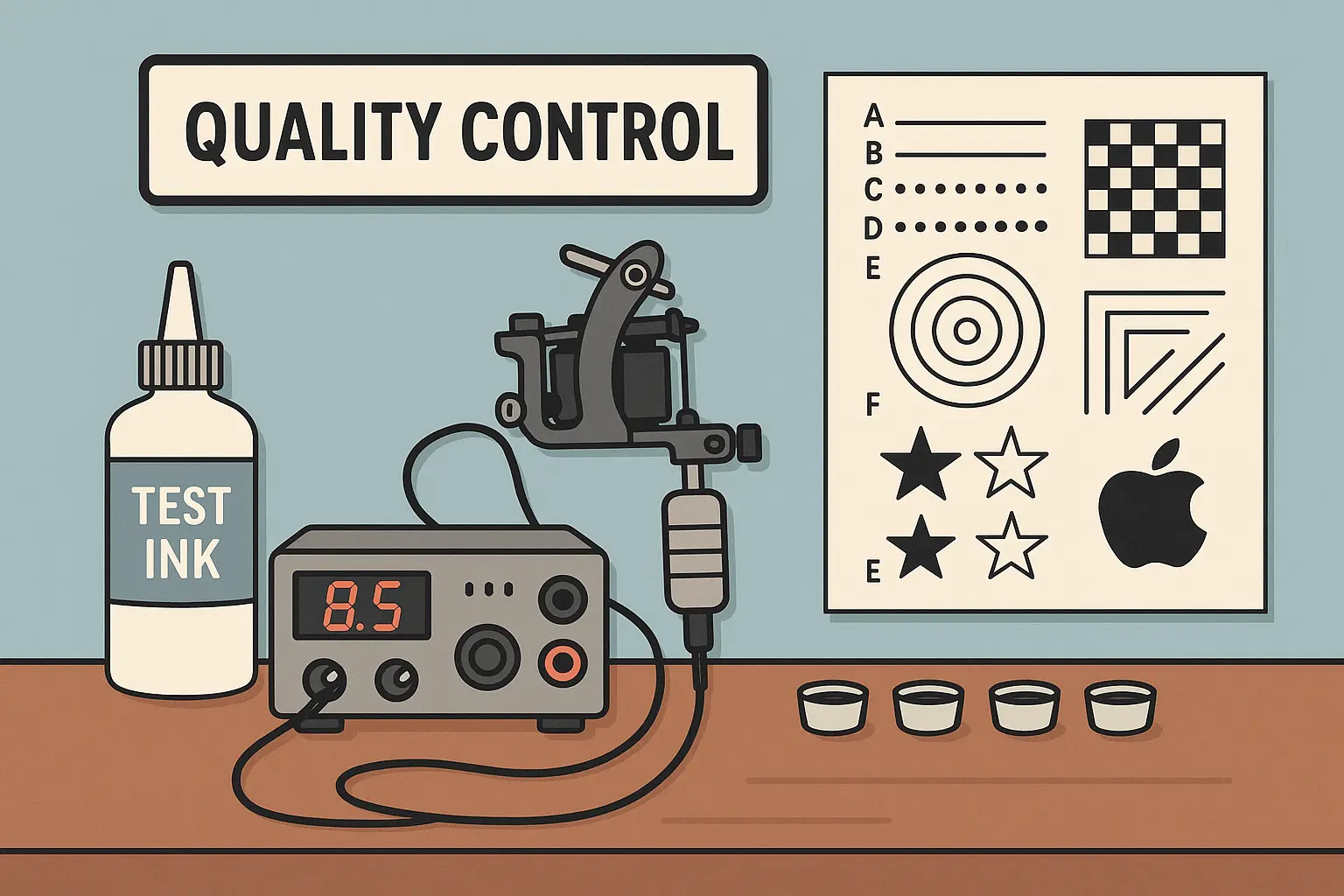

Running a shop taught me that consistency is everything, but it’s harder than it sounds. You’ve got different artists with different techniques, paper that behaves differently depending on the weather, and batches that sometimes just suck for no apparent reason. I learned to test every new batch because nothing ruins your day like discovering mid-session that your entire paper supply is garbage.

Professional tattoo shop workflows involve inventory management, quality control protocols, and client communication systems that most discussions completely overlook. I’ve discovered that the integration of tattoo paper systems into daily operations can make or break a shop’s efficiency and client satisfaction.

Successful shop operations require understanding all cost factors, including how tattoo pricing strategies should account for material quality and workflow efficiency to maintain profitability while delivering exceptional results.

Most shops focus on equipment and talent while completely ignoring the systems that support consistent daily operations. The difference between struggling shops and thriving ones often comes down to these overlooked operational details.

Quality Control Systems That Prevent Disasters

Professional shops require consistent stencil quality across different paper batches, environmental conditions, and multiple artists. Without systematic quality control approaches, you’ll face frustrated clients and wasted time from failed transfers.

Implementing quality control for tattoo paper involves more than just visual inspection – you need measurable standards and systematic testing protocols that catch problems before they affect paying customers.

Storage Protocols That Preserve Paper Quality

I learned about proper storage the hard way during a humid summer. Left a box of paper in my car overnight, and the next morning it was basically useless – wouldn’t transfer properly, adhesive was all weird. Cost me $150 and taught me to treat this stuff like it’s made of gold. Now I’m that guy who checks the humidity in my storage room obsessively.

Thermal tattoo paper degrades rapidly in humidity above 60% or temperatures exceeding 85°F, requiring climate-controlled storage systems that many shops neglect until quality issues emerge and start costing money.

Professional Storage Protocol:

-

Maintain humidity below 60%

-

Keep temperature under 85°F

-

Use airtight containers with desiccant packs

-

Rotate stock using FIFO method

-

Monitor environmental conditions daily

-

Separate different paper types to prevent contamination

Batch Testing That Catches Problems Early

Professional workflows include systematic testing of each new tattoo paper batch using standardized test patterns to verify transfer density, adhesion properties, and durability before client use. This approach catches problems before they affect paying customers.

Client Communication Tools You’re Not Using

Advanced tattoo papers serve as powerful communication tools between artists and clients, with specialized papers designed for client approval processes and expectation management. These tools can dramatically reduce revision requests and improve client satisfaction.

Proof Paper Systems That Save Time and Money

I started talking to other artists about this, and pretty much everyone who uses proof papers says the same thing – way fewer clients coming back asking to move things around or make changes. Sarah at the shop next to mine swears by them. Says she went from spending half her consultation time dealing with placement changes to maybe 10% of her time.

Specialized proof papers allow clients to wear test stencils for 24-48 hours, experiencing placement and sizing before committing to permanent work, reducing revision requests by up to 70% according to shops that use them.

Documentation Integration for Portfolio and Marketing

Modern shops use photographable stencil papers that maintain visibility under various lighting conditions for portfolio documentation and social media marketing purposes. This detail makes a big difference in presentation quality.

Sustainability Approaches That Actually Work

I’ll be honest – I didn’t really think about the environmental stuff until my kid started asking me about recycling at work. Made me realize how much paper waste we generate, and I started looking into biodegradable options. They’re not perfect yet, but they’re getting better, and it feels good to not contribute quite as much to landfills.

Environmental concerns drive innovation in biodegradable tattoo papers and waste reduction systems that maintain professional quality while reducing ecological impact. Going green doesn’t have to mean compromising on quality.

Environmental consciousness extends beyond materials to overall shop practices, including how proper aftercare education reduces waste from healing complications and ensures sustainable client relationships.

Biodegradable Options That Don’t Compromise Quality

New plant-based tattoo paper decomposes within 90 days while maintaining transfer quality, though they require modified storage conditions and shorter shelf lives than traditional synthetic papers.

Recycling Programs Designed for Tattoo Shops

Specialized recycling programs for used thermal papers separate carbon-coated materials from base papers, though contamination from skin contact limits recycling effectiveness to base materials only.

Looking at the complexity of professional tattoo paper systems, I realize that starting with optimized digital designs makes everything else work better. Tattoo Generator IQ provides designs specifically formatted for various professional paper systems, including proper resolution settings and line weight optimization that reduces waste from failed transfers. Whether you’re using high-end thermal systems or experimenting with DIY methods, having designs engineered for successful stencil creation eliminates the guesswork that frustrates both artists and clients.

For artists working with intricate designs, understanding specialized applications helps bridge the gap between traditional artistry and modern silhouette tattoo paper technology for exceptional results. The integration of hand-drawn tattoo techniques with advanced paper systems creates possibilities that neither approach could achieve alone.

Final Thoughts

Look, I know this is a lot of information, and honestly, it took me years to figure most of this stuff out through trial and error. You don’t need to become a paper scientist overnight, but understanding even the basics will save you money, time, and a lot of frustration.

What strikes me most is how much the industry has evolved beyond simple carbon paper transfers. We now have biodegradable options, medical-grade temporary testing systems, and precision cutting that achieves accuracy levels that would have been impossible just a few years ago. Yet many artists and shops still treat paper selection as an afterthought.

Whether you’re working with professional thermal systems or experimenting with DIY approaches, understanding the underlying principles makes all the difference. Temperature control, humidity management, proper storage, and quality testing aren’t just technical details – they’re the foundation of consistent, professional results that keep clients happy and coming back.

Start with getting your storage right and testing your temperatures – those two things alone will solve 80% of the problems most people have with stencils. The integration of these paper technologies into professional workflows represents a huge opportunity for shops willing to invest in proper systems and training. From proof papers that reduce revision requests to multi-layer stencil systems that organize complex work, the right approach to tattoo paper can transform both efficiency and client satisfaction in ways that go far beyond just making better stencils.